Fertilisers with lower environmental impacts and reduced costs for farmers are being developed by University of Adelaide researchers in the world-first use of the new advanced material graphene as a fertiliser carrier.

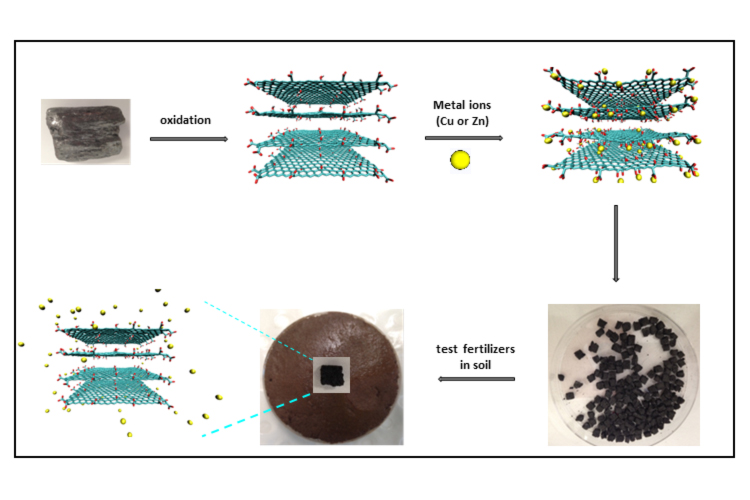

In partnership with industry, the researchers have demonstrated effective slow release fertilisers can be produced from loading essential trace elements onto graphene oxide sheets.

Using graphene as a carrier means the fertilisers can be applied in a more targeted fashion, with overall increased fertiliser efficiency and great nutrient uptake by the plants. The graphene-based carriers have so far been demonstrated with the micronutrients zinc and copper. Work is continuing with macronutrients such as nitrogen and phosphate.

“Fertilisers that show slower, more controlled release and greater efficiency will have reduced impact on the environment and lower costs for farmers over conventional fertilisers, bringing significant potential benefit for both agriculture and the environment,” says Professor Mike McLaughlin, Head of the University of Adelaide’s Fertiliser Technology Research Centre at the Waite campus.

“Our research found that loading copper and zinc micronutrients onto graphene oxide sheets was an effective way to supply micronutrients to plants. It also increased the strength of the fertiliser granules for better transport and spreading ability.”

Professor Dusan Losic, nanotechnology leader in the University’s School of Chemical Engineering and Director of the University’s Australian Research Council (ARC) Research Hub for Graphene Enabled Industry Transformation, says: “Graphene is a novel new material only discovered in 2004 and has incredible properties, including a very high surface area, strength and adaptability to bind to different nutrients. We started exciting research on a broad range of applications of graphene four years ago – this is the first time graphene has been developed as a carrier for fertiliser nutrients.”

The research, carried out by PhD student Shervin Kabiri, has been published in the journal Applied Materials and Interfaces. It is a collaboration between the University of Adelaide’s Fertiliser Technology Research Centre and the University’s Australian Research Council Research Hub for Graphene Enabled Industry Transformation.

The Fertiliser Technology Research Centre was established in 2007 in partnership with The Mosaic Company, the world’s largest combined producer of phosphate and potash, to develop and evaluate more efficient fertiliser products. A new five-year, $8.5 million partnership agreement was reached with The Mosaic Company in 2015. Mosaic has an option to license the new technology and is further examining the use of graphene-based materials in fertilisers.

“This decade-long partnership is testament to the University’s strength in this area of research and our success in partnering with industry for research translation that benefits the wider community,” says Professor Mike Brooks, Deputy Vice-Chancellor Research. “Combining plant research with our new Graphene Research Hub is a great example of how the University assembles interdisciplinary teams to deliver innovation solutions for industry.”

Professor McLaughlin says: “It’s still early days but there is no doubt that fertilisers with release rates more tailored to crop demand, and fertilisers with greater physical strength and robustness, will both improve grower efficiency of fertiliser application and efficiency of nutrient uptake.

“Successful commercialisation will depend on cost of graphene/graphene oxide and the ability to scale this process up, and integrate it into the commercial fertiliser production process.”

Professor Mike McLaughlin

Email: michael.mclaughlin@adelaide.edu.au

Professor Dusan Losic

Email: dusan.losic@adelaide.edu.au

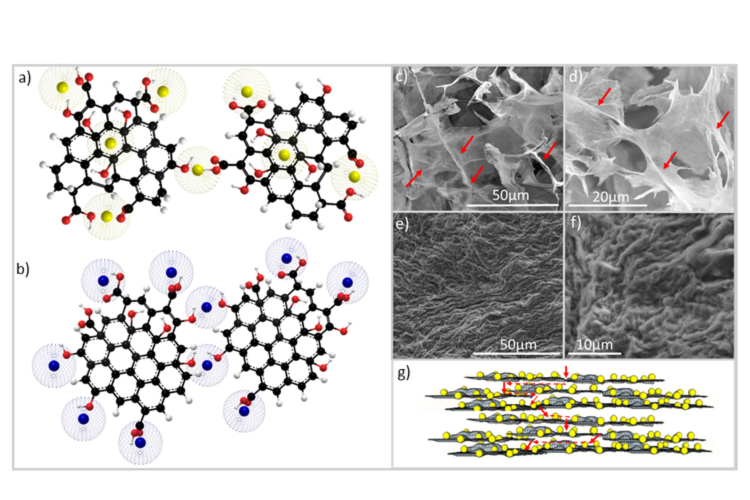

Lead feature image: Schematic diagram of GO sheet interactions with (a) Zn2+ ions and (b) Cu2+ ions and SEM images of (c) rolled Zn and Cu-loaded GO sheets, (d) rolled and wrinkled GO sheets, and (e) low-resolution and (f) high-resolution SEM images of Cu-loaded GO sheets stacked on top of each other, and (g) schematic of water penetration through the stacked structure of fertilisers granules.